Plastic & Metal Processing

Innovative metal and plastic processing are key technologies, for instance for the automotive, aircraft and high-speed train industries.

Processes for the production of lightweight parts and components form the core of K.K. IRISU's (ILLIES) portfolio.

Applications include “near-netshape” metal forming processes for highly precise parts' geometry, (selective) press hardening, thermoforming and composite technologies.

Car Body Parts

Furnaces and automation for press hardening lines, hydroforming lines, high quality laser welding systems for flat and round part

- Furnaces For Press Hardening

- Automation Of Press Hardening Lines

- Hydroforming

- Laser Welding For Tailored Blanks And Tubes

- Machinery For Production Of Carbon And Glass Fiber Parts

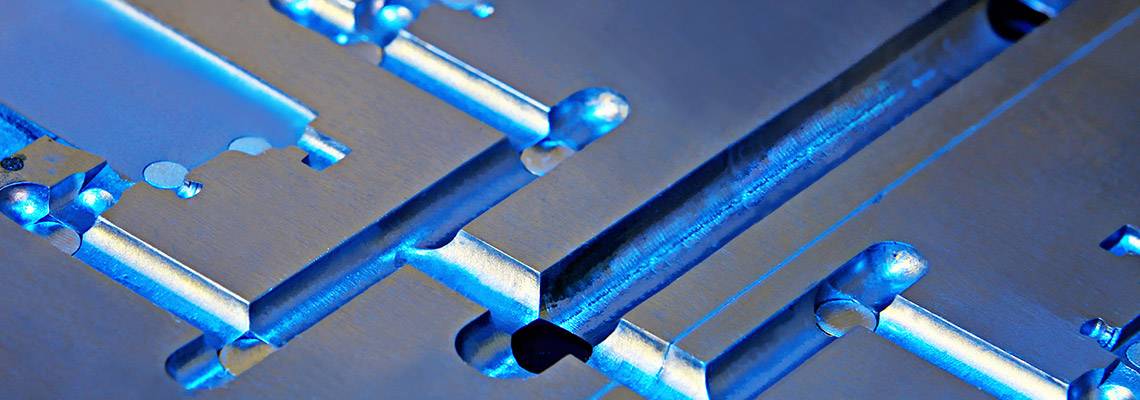

Engine & Power Train

Manufacturing, forming by spinning, flow-forming, hub-forming, axial forming, swaging, furthermore calibrating, welding, forging, and quenching of a big variety engine and powertrain part

- Spinning

- Flow-Forming

- Hub-Forming

- Axial Forming

- Swaging

- Step Set Dies

- Stepped Tools For Lamellar Casing For Automatic Transmissions

- Forging (Cold, Semi Hot And Hot)

- Calibrating With Hydraulic Press

- Quenching

Others

- Fixture Hardening

- Superplastic Forming And Diffusion Bonding

Tube industry

Range of solutions for the production of large longitudinal welded pipes (LSAW)

- Presses / Bending Presses

- Welding

- Automation

- System Integrator

- Milling And Cutting